When I got to the site, he was working on filling in the foam around the edges. You really can't tell from this picture, but he was covered in little white foam dots!

Cutting the last sheet of foam into smaller strips. Check out the thin piece of foam at the bottom left of this picture...that's how tiny of a strip he cut off one piece to make it fit!

Out of the 8 giant bundles of HydroFoam that we bought, this is all the waste there was! No expensive foam wasted here!

At lunchtime, we went to another plumbing supply house in Saratoga - Jim didn't like the floor drains they had at the other store. While Jim was looking at drains, I went into the kitchen and bath showroom and browsed through all the gorgeous countertops, faucets, sinks and appliances!

After we got back, I got busy putting more staples in - we put in 300 yesterday and I put probably 250 in today!

The Pex is all stapled and totally finished!

Time to attach the forms to the front of the garage door openings to get ready for concrete. Jim fastened the steel to the block with concrete anchor bolts.

Working on the other opening...

Then he reattached the boards so that he could put the partitions back up to keep out any random animals.

Time for gravel to hold the steel form in place.

Piling it up in front of the form and getting it all level.

Then it was time to work on some plumbing. We were remembering how we started the plumbing way back when! This was kind of tough - Jim had to saw through the pipe at the precise level so that the clean-out drain could be put in and be level with the concrete when it's poured.

Trying it out...

Of course the drain went right by the Pex so Jim had to cut a few foam tabs off and reroute the Pex a little - the staples helped with keeping everything in place.

Putting the primer on...

...and then the glue.

All finished!

The floor drain was a little harder. Again, we installed these stacks back when there was nothing around but dirt! You try your best to get things straight but Jim wasn't quite happy with this stack. So I ran home and got the heat gun - a scary thought next to all this foam and plastic tubing! He used a tool tray to cover up the Pex and then positioned the heat gun next to the pipe. You could smell the foam heating up and it sort of shrunk a little around the edges but it was all fine.

Jim got the pipe perfectly straight and put the fancy new drain on top just to be sure. He'll need his multi-purpose saw to cut this pipe and it was still at home, so that's a job for another day.

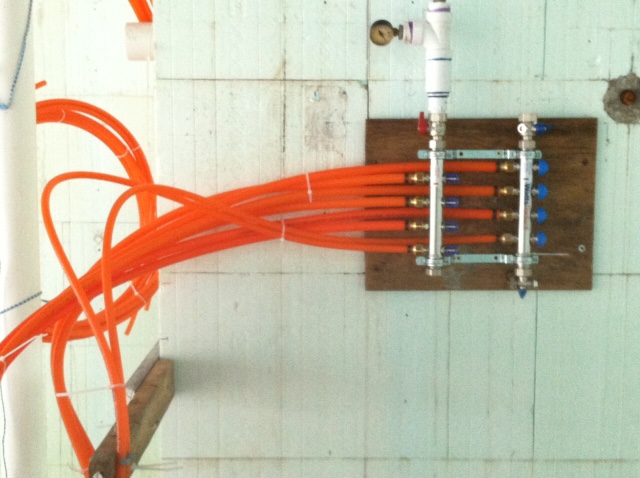

At the end of the day, Jim used his new correct fittings and started working on attaching the Pex to the manifold.

All finished!

We were so hoping that we could do concrete tomorrow - the weather would have been perfect according to the forecast. But the contractor had other jobs so we'll be at his mercy. Unfortunately, next week the temperatures start creeping up into the upper 80s which isn't good for concrete, so we'll have to see how it goes. Thankfully, unlike last time, it won't hold us up - we will start back on sheathing tomorrow!

Can't end this without saying Happy Birthday to my Mom - we love you much!

|

| High 72/Low 50 |

It's all coming together bit by bit, and it’s building up into a really welcoming place. One can easily see all the work and dedication you have put into its parts and foundations. Don't hurry yourself with the concrete though. What matters is that you make sure you have a house that is worth calling your own. Cheers!

ReplyDeleteWillard Evans @ WOW! Homes